Enhancing Your Environment: The Power of Industrial Desiccant Dehumidifiers

In today's fast-paced world, maintaining optimal humidity levels is essential for both comfort and health. Whether in a home, office, or industrial space, excess moisture can lead to a variety of problems, including mold growth, damage to property, and uncomfortable living conditions. Enter industrial desiccant dehumidifiers, a revolutionary solution designed to tackle these moisture problems efficiently.

Understanding Industrial Desiccant Dehumidifiers

At their core, industrial desiccant dehumidifiers utilize a desiccant material—substances that absorb moisture from the air—to remove excess humidity. Unlike traditional refrigerant dehumidifiers that rely on cooling coils, desiccant dehumidifiers work effectively in low-temperature environments and offer a much lower relative humidity level.

The Science Behind Desiccant Technology

Desiccants such as silica gel, activated alumina, and calcium chloride are typically used due to their high absorption capabilities. When air passes through the dehumidifier, the moisture is drawn into the desiccant, leaving behind dry air to circulate back into the environment. This process not only reduces humidity but also enhances the overall air quality.

Benefits of Using Industrial Desiccant Dehumidifiers

Investing in industrial desiccant dehumidifiers offers numerous benefits that far surpass traditional dehumidification methods.

1. Superior Moisture Control

One of the most significant advantages is the ability to maintain low humidity levels consistently. This is crucial for industries such as food production, pharmaceuticals, and electronics, where moisture control is paramount to product integrity and safety.

2. Energy Efficiency

Despite their advanced capabilities, these systems tend to consume less energy than traditional dehumidifiers. This is primarily due to their ability to operate effectively without needing to cool the air, making them a cost-effective choice for larger industrial setups.

3. Enhanced Longevity of Equipment and Materials

Excess humidity can lead to corrosion and degradation of sensitive equipment. By maintaining optimal humidity levels, industrial desiccant dehumidifiers help enhance the lifespan of costly machinery and raw materials.

4. Flexible Installation Options

These dehumidifiers can be easily integrated into existing HVAC systems or can operate independently, providing flexibility in application. They are suitable for a range of environments, from large warehouses to small production facilities.

Applications of Industrial Desiccant Dehumidifiers

The versatility of industrial desiccant dehumidifiers allows them to be used across various sectors:

- Manufacturing: Protect equipment and products from excess moisture.

- Food Industry: Preserve the quality and safety of food products.

- Pharmaceuticals: Ensure that medicines and vaccines are stored in optimal conditions.

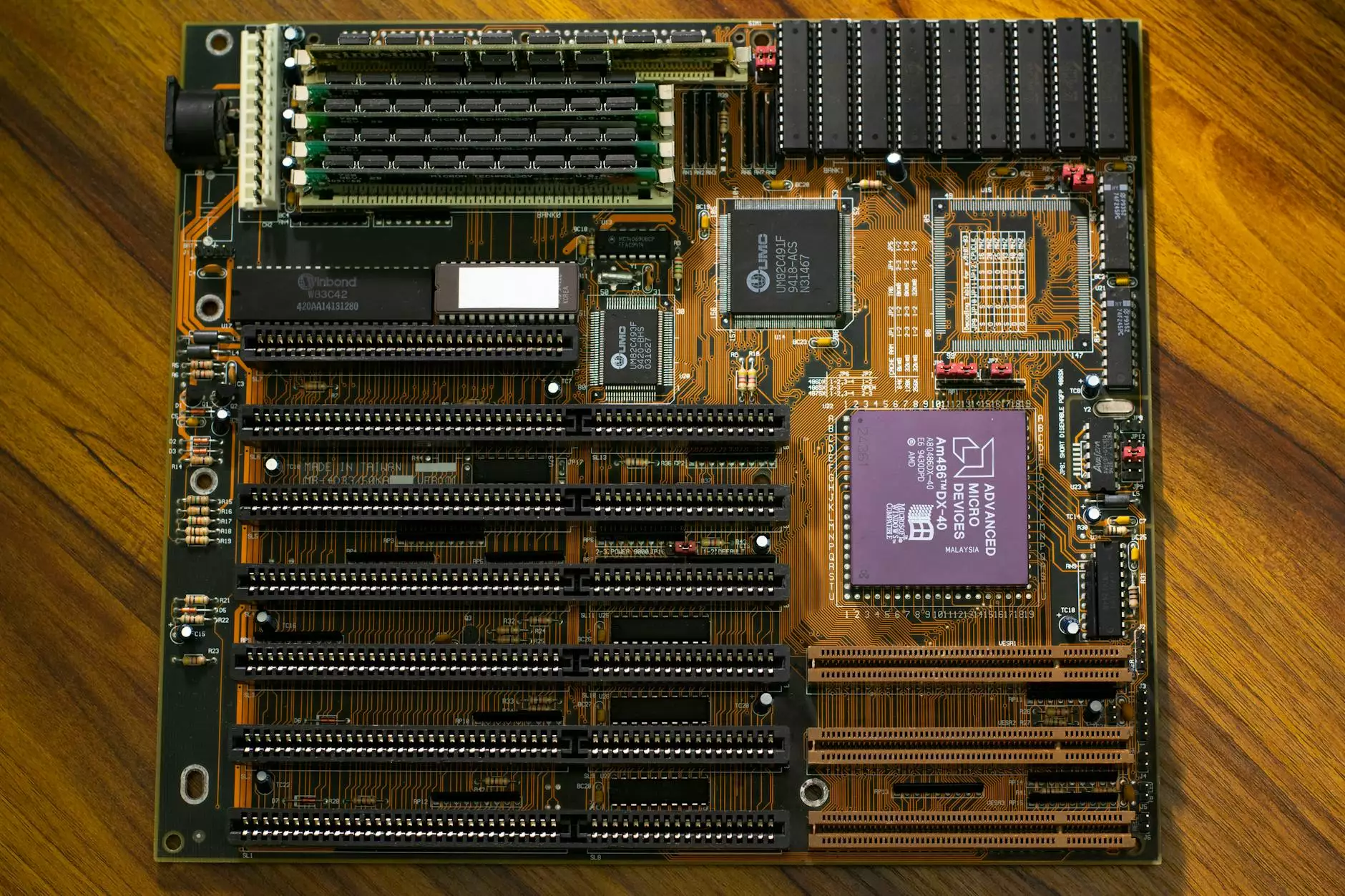

- Data Centers: Maintain humidity levels to protect sensitive electronic equipment.

- Storage Facilities: Shield valuable items from mold and mildew.

Choosing the Right Industrial Desiccant Dehumidifier

When selecting an industrial desiccant dehumidifier, consider the following factors to ensure you choose the best fit for your needs:

1. Size and Capacity

Assessing the size of the area and the specific humidity level requirements is essential. A unit that is too small will be ineffective, while one that is too large may lead to unnecessary energy consumption.

2. Operating Conditions

Understanding the environment in which the dehumidifier will operate (temperature, airflow, etc.) is critical for optimal performance. Desiccant dehumidifiers excel in low temperatures where traditional units may fail to perform effectively.

3. Maintenance and Lifespan

Consider the maintenance requirements and the expected lifespan of the units. Selecting a unit that offers easy maintenance can save time and costs in the long run.

4. Brand Reputation and Reliability

Opt for reputable brands known for their quality and reliability. Researching customer reviews and testimonials can provide valuable insights into product performance.

Installation and Maintenance Tips

Proper installation and ongoing maintenance of your industrial desiccant dehumidifier can significantly affect its efficiency and lifespan. Here are some essential tips:

Installation:

- Ensure the unit is installed according to the manufacturer’s specifications.

- Position the dehumidifier in a location with unobstructed airflow.

- Connect to a proper drainage system, if necessary, for the collected moisture.

Maintenance:

- Regularly check the desiccant material for saturation and replace as needed.

- Inspect filters and fans to ensure they are clean and functioning optimally.

- Schedule periodic professional inspections to maintain long-term performance.

Impact on Health and Well-being

Maintaining optimal humidity levels is not just about preserving materials and equipment; it's also crucial for the health and well-being of individuals. High humidity can lead to mold growth, which poses serious health risks, including respiratory issues and allergic reactions. By using industrial desiccant dehumidifiers, you can create a healthier environment, reducing the risk of health problems associated with high humidity.

Conclusion

In conclusion, the adoption of industrial desiccant dehumidifiers represents a forward-thinking approach to managing humidity in both industrial and residential spaces. Their ability to provide stable, low humidity levels can protect physical assets, improve air quality, and encourage a healthier living environment. Investing in these systems not only improves comfort levels but also ensures the longevity and efficiency of your operations.

For further information and to explore a variety of options, visit Climatronics, where we specialize in providing top-of-the-line dehumidification solutions tailored to your specific needs.